DAYTON, Ohio—(March 27, 2020) AIMS Metrology, a Dayton, Ohio-based OEM for coordinate measuring machines, announced today it is making its’ design, engineering, rapid prototyping, machine tool capacity, inspection and measurement capabilities available to produce parts needed to support healthcare providers during the COVID-19 pandemic.

DAYTON, Ohio—(September 4, 2019) AIMS Metrology, an OEM for 5-axis coordinate measuring machines, will hold a Metrology Forum at its Dayton, Ohio production facility October 2-3, 2019 from 9 a.m. to 4 p.m. Manufacturers are invited to attend the event which will feature guest speakers from Honda and Renishaw. Visitors will also get the chance to see firsthand the unique technology behind AIMS’ Revolution Series 5-axis LM and HB CMMs.

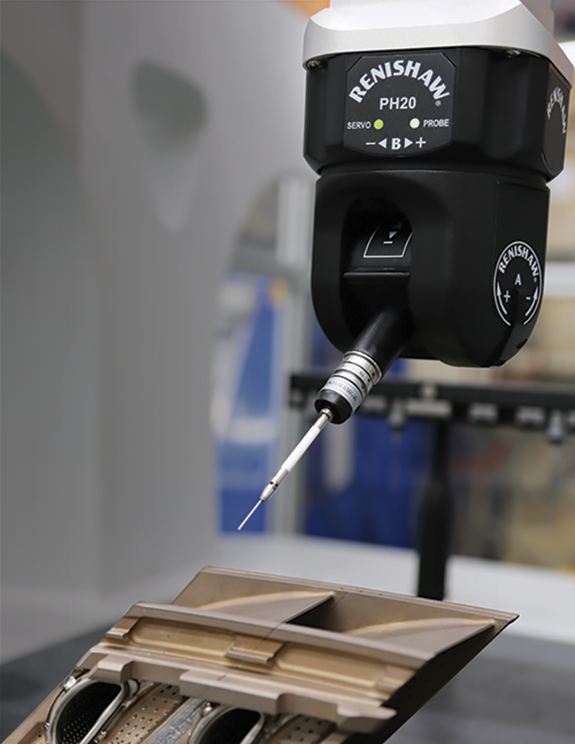

DAYTON, Ohio—(July 22, 2019) Motch & Eichele is the exclusive distributor for AIMS Metrology’s coordinate measuring machines (CMMs) for the territories of Ohio, Kentucky and Western Pennsylvania. AIMS products will include the laboratory-grade Revolution Series LM equipped with Renishaw’s 5-axis REVO 2 scanning head and SFP2 probe and the Revolution Series HB, the industry’s only mobile 5-axis CMM, built and designed with Renishaw’s PH20 5-axis touch trigger system. Motch & Eichele will also offer AIMS’ Renishaw Equator 300 gauging system for manual and automated applications.

DAYTON, Ohio—(May 15, 2019) Five-axis coordinate measuring machine OEM AIMS Metrology announced the hiring of Chris Brown as national sales manager. Brown has more than three decades of experience in quality inspection equipment, service and support. Brown represented Sheffield Corp. gauges and measuring systems until 2004. Brown continued to represent and service the line under the name Sheffco until 2010. He has also distributed Renishaw 5-axis products since 1988.

DAYTON, Ohio—(April 25, 2019) Until now fabricators conducting surface finish measurements have had to use hand-held sensors or move a part to a dedicated measuring machine. To help companies reclaim lost production time, AIMS Metrology has equipped its Revolution Series LM coordinate measuring machine (CMM) with a Renishaw 5-axis REVO 2 head and the new SFP2 probe. Because the SFP2 is interchangeable with other probe options, it gives manufacturers the flexibility to inspect a diverse range of features on one CMM. The SFP2 automates surface finish measurement for reduced part handling and higher throughput.

The Revolution HB from AIMS anchors the Renishaw 5-axis PH20 touch-trigger indexing head and probe with a vibration-resistant base as it quickly scans and performs discrete point measurements on parts like this aerospace component. Courtesy of FF Journal.

Written by Lynn Stanley

Until recently, conventional 3-axis CMMs proved largely sufficient. A probe attached to a third moving axis measured a part’s physical characteristics. But slower cycle times, limited flexibility [5 to 7 1/2 degrees of polarity] and lack of mobility have proved problematic in an Industry 4.0 environment.

DAYTON, Ohio—(March 5, 2018) With lead times shrinking and the demand for parts with multiple features and tighter tolerances growing, fabricators have little time to spare for new equipment demonstrations. Yet the need to find the right quality inspection equipment is higher than ever. That’s why ABLE Machine Tool Sales Inc., the New England distributor for Dayton, Ohio-based AIMS Metrology’s Revolution Series coordinate measuring machines (CMM), is bringing the technology to its customers’ doorsteps.

Written by MARK GEARDING and originally published in Quality Magazine. Visit the original article at https://www.qualitymag.com/articles/94252-taking-measure.

Today’s on-the-go-consumers demand products that can multitask, from portable meal kits and one-minute makeup to smartphones that can measure your heartbeat or control your thermostat. Pocket-sized, titanium survival tools equipped with items like a knife, screwdriver, flashlight and can opener have joined the ranks as common, everyday carry items.

AIMS Metrology, an OEM for coordinate measuring machines, has achieved ISO/IEC 17025:2005 accreditation for calibration from the ANSI-ASQ National Accreditation Board. ISO/IEC 17025:2005 covers testing and calibration performed using standard, non-standard and laboratory-developed methods.