June 27, 2022 - Rapid part changes, raw material bottlenecks and labor shortages continue to drive demand for multisensor inspection with the option to automate. AIMS Metrology will demonstrate its full range of turnkey 5-axis coordinate measuring machines at Booth # 135536. The OEM’s Revolution Series Summit 10.10.10, LM and HB provide accurate, flexible three-dimensional inspection of small to large in-process and post-process parts on the shop floor, in the lab or in an automated cell.

To read the full story on SME, please click here.

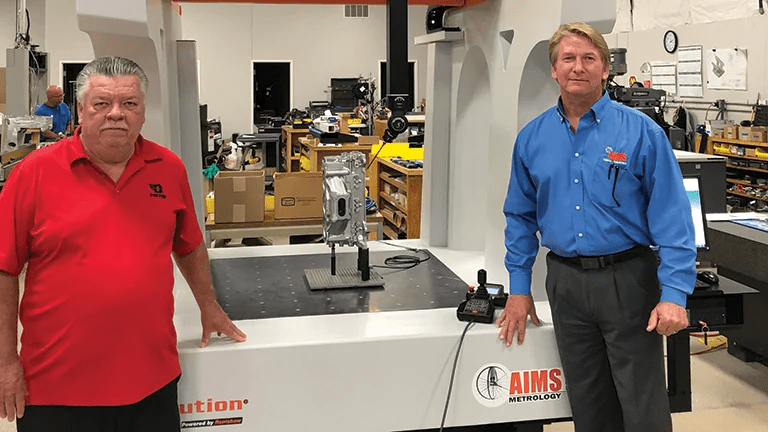

In 2016, Honda Transmission, an automotive OEM based in Russells Point, Ohio, began looking for ways to update their quality inspection methods. Inspections were made using a hard fixture with bar gages, which was costly and took too much time. On top of that, they also couldn't collect live data.

CAMBRIDGE, Ontario—(August 3, 2021) 1Source Metrology will represent AIMS Metrology’s Revolution Series 5-axis mobile HB and its new 5-axis Summit 10.10.10 coordinate measuring machines. The Cambridge, Ontario distributor combines more than a century of industrial metrology experience under one roof. Its services include CMM sales, programming, certified inspection, software training, retrofits, reverse engineering, data collection solutions, fixturing and accessories sales.

DAYTON, Ohio—(July 8, 2021) AIMS Metrology engineers will talk with manufacturers about the Dayton, Ohio-based OEM’s 5-axis coordinate measuring machine solutions at Booth 3213 at EASTEC 2021. In 2020, AIMS introduced its’ newest addition, the Summit 10.10.10. Equipped with a 5-axis REVO-2 dynamic scanning probe and 1 meter cubed capacity, the Summit has the capacity to handle high volume, large parts inspection on the job shop floor.

CAMBRIDGE, Ontario—(August 3, 2021) 1Source Metrology, a representative of Dayton, Ohio-based AIMS Metrology, demonstrated the Revolution Series mobile, 5-axis HB coordinate measuring machine at Booth #2423 at CMTS 2021. The Cambridge, Ontario distributor combines more than a century of industrial metrology experience under one roof. Its services include CMM sales, programming, certified inspection, software training, retrofits, reverse engineering, data collection solutions, fixturing and accessories sales.

DAYTON, Ohio—(Oct. 1, 2021) As manufacturers continue to automate inspection, companies are also looking for solution-oriented OEMs that can provide service and support. AIMS Metrology will feature its Revolution Series 5-axis coordinate measuring machines at Booth 714 at The Quality Show. Its’ new Summit 10.10.10, equipped with a 5-axis REVO-2 dynamic scanning probe and 1 meter cubed capacity, is the largest shop floor CMM in the industry. AIMS turnkey solutions include fully automated inspection cells.

DAYTON, Ohio—(September 17, 2021) AIMS Metrology, a 5-axis coordinate measuring machine OEM, appointed John Bishop regional sales manager. He will provide service and support for customers in Tennessee, Georgia, Alabama, Mississippi, Louisiana, Arkansas and Missouri. Bishop has more than 20 years of experience in the metrology industry.

Coordinate Measuring Machine (CMM) manufacturer AIMS Metrology has announced the acquisition of the assets of Measurement Specialties Inc. (MSI). AIMS and MSI are both located in Dayton, Ohio in USA. MSI calibrate, certify and program CMMs, with a specialization in Sheffield machines, while also providing both retrofit and repair services.

Dayton, Ohio—(Sept 4, 2020) AIMS Metrology was featured in a Metrology News article this week detailing a partnership with Honda Transmission.

Dayton, Ohio—(Sept 1, 2020) AIMS Metrology was featured in the Dayton Business Journal detailing the launch of the new Summit 10.10.10.

.jpg)