A coordinate measuring machine (CMM) measures the geometry of certain physical objects along their X, Y, and Z axes. The CMM’s probing system scans objects at precise points to determine dimensions, angularity, size, profile, and angularity. These capabilities have many applications across different industries. In this blog post, we’ll explain the benefits of CMM technology and the types of machines we offer.

Why Should I Purchase a CMM?

Traditional manual inspection is severely limited compared to CMMs. Human error and inaccuracy are major concerns, and some objects feature designs that are too complex for manual methods to capture. In addition, handheld inspection lacks the consistency to detect improperly manufactured products before they ship to customers. A CMM would address all of these issues while increasing efficiency.

The following are some specific benefits of using a CMM.

Save Time and Money

With a CMM, you’ll no longer need a dimensional lab. You also won’t need to remove large parts from shop floors to take accurate measurements. CMM technology will produce more exact results even with highly complex objects, saving you time and money.

Improved Quality Verification

Modern CMM technology allows for in-depth 3D inspections, computer-aided design comparisons, tool certifications, and other processes that optimize quality verification. These quality checks ensure that you’re consistently making top-quality products.

More Floor Space

Ample shop floor space is critical for any operation. Mobile CMMs make it easier to inspect large components that take up a lot of space and are difficult to move. Aerospace, automotive, and manufacturing industries in particular benefit greatly from advanced CMMs.

Consistent Reliability

CMMs are dependable tools in any inspection environment, especially when taking 3D measurements. Whether you use contact or contactless scanning methods, CMMs feature high thermal stability, which provides the reliability and accuracy you need from this equipment.

Revolution, American-Made CMM Technology

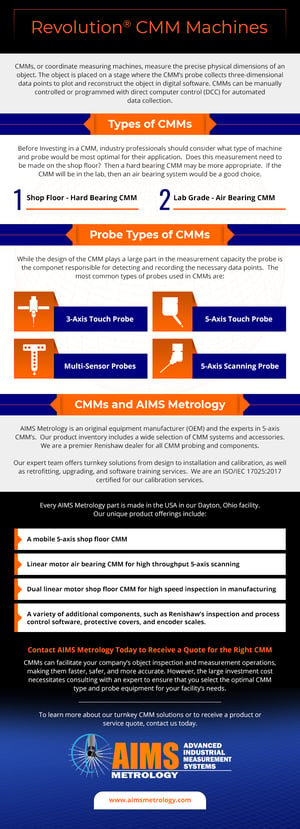

At AIMS Metrology, we offer several types of CMMs depending on our customers’ needs:

- Revolution® HB Shop Floor CMM: This American-made CMM is a 5-axis shop floor model that can measure spaces unreachable by hand. For optimal mobility, it includes a roll-around stand and lockable casters to hold it in place.

- Revolution® Linear Motor CMM: The LM Series provides more efficient 5-axis measurements than traditional air-bearing systems. These CMMs feature linear motors that reduce maintenance requirements, in contrast to a conventional belt and pulley systems.

- Summit 10.10.10: This shop floor CMM can measure particularly large and heavy components. Its extra-large capacity can measure objects up to one cubic meter and 2,200 kg in weight.

- Revolution® Air Bearing Large Bridge CMM: This large bridge CMM comes in multiple sizes and accurately measures large components.

Experience the Best CMM Technology with AIMS Metrology

The right CMM technology can increase accuracy, speed, and consistency in any inspection application. At AIMS Metrology, we offer CMM installation, calibration, repairs, warranty service, and financing to meet our customers’ requirements. We also provide comprehensive turnkey solutions and contract programming.

If you would like to get started with a unique solution for your application, request a quote from us today.

Editor's note: Originally published April 2018, updated May 2, 2019