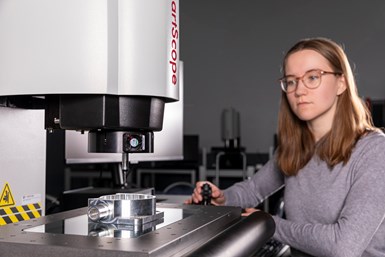

In exciting news: AIMS has renewed our ISO 17025 calibration accreditation – this time to include our Comparators alongside our CMMs!

AIMS strives for the upmost quality and care for the customers we service, and the renewal and expansion of our 17025 accreditation ensures that we can do just that. The highest standards of excellence in all aspects is what customers have come to expect from AIMS, and we are happy to prove them right. The team you have known and trusted at CCP is certified under the AIMS accreditation for all your Comparator calibration needs.

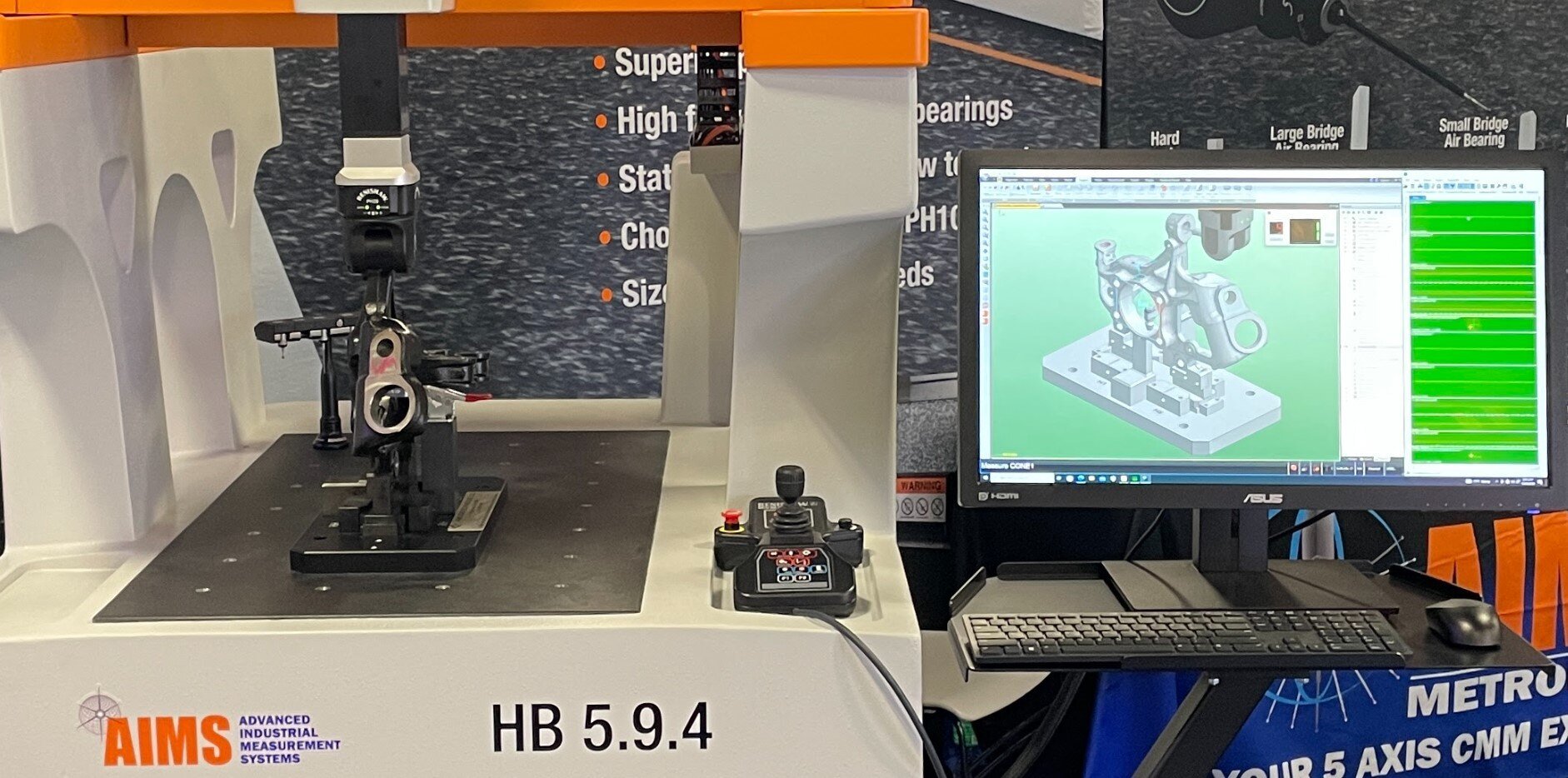

IMTS is almost here and AIMS will be displaying some of the newest technologies, including Multisensor Measurement on our HB CMM. We will be in Booth 134342 in the Quality Pavilion.

AIMS was recently featured in the SME article - Coordinates to the Future. This is great look into the future of CMM needs and the direction of this technology moving into the future.

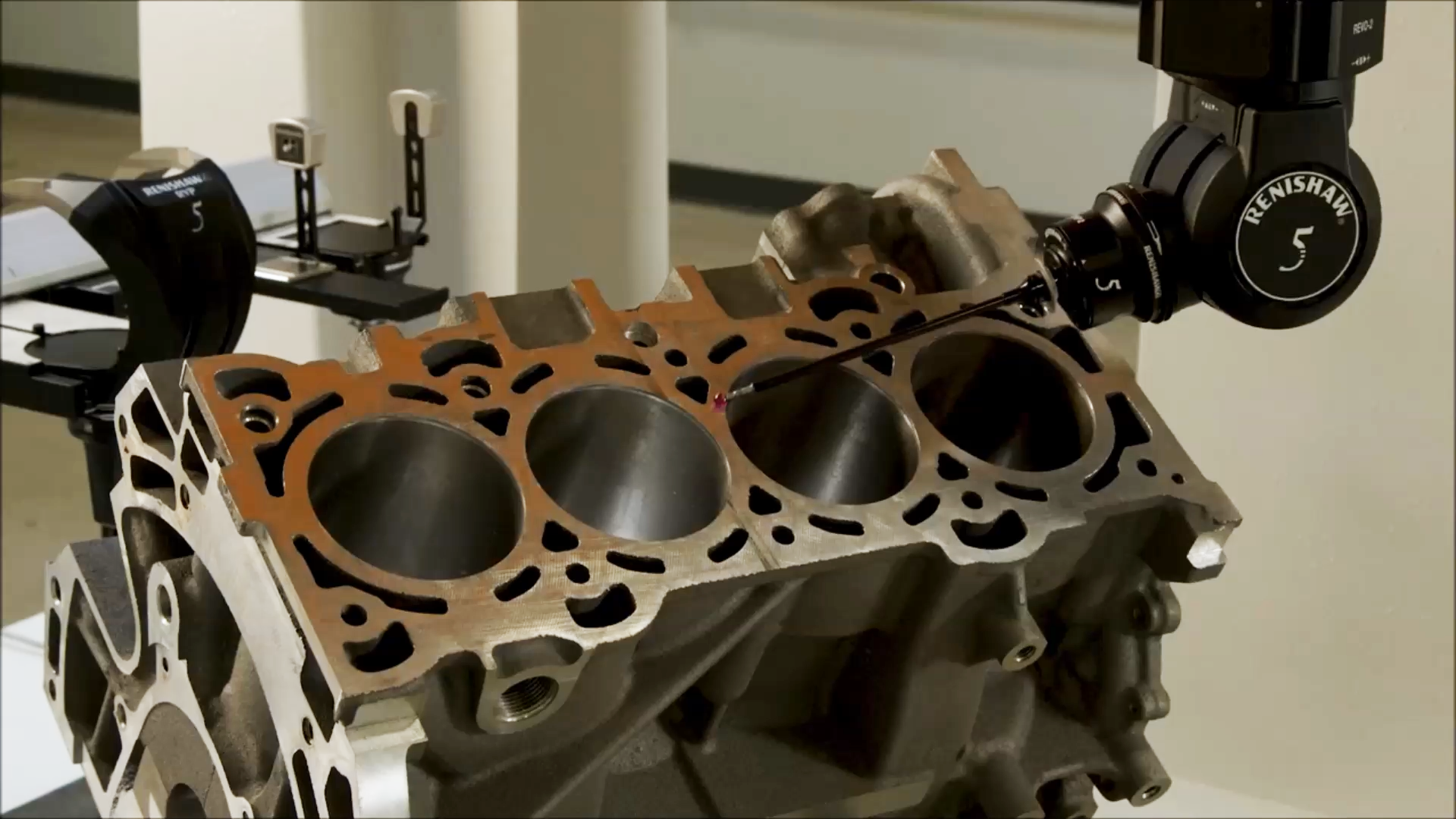

Well-documented data and information management is more important than ever. From part quality to inventory locations, job shops and manufacturers need progressive tools to help them navigate rapid changes in a digital landscape. Rising demand in markets such as machinery manufacturing, transportation, electronics and aerospace in particular, are prompting companies to adopt 5-axis coordinate measuring machines (CMMs) to streamline and automate parts inspection and measurement.

To read the full article on FF Journal, please click here.

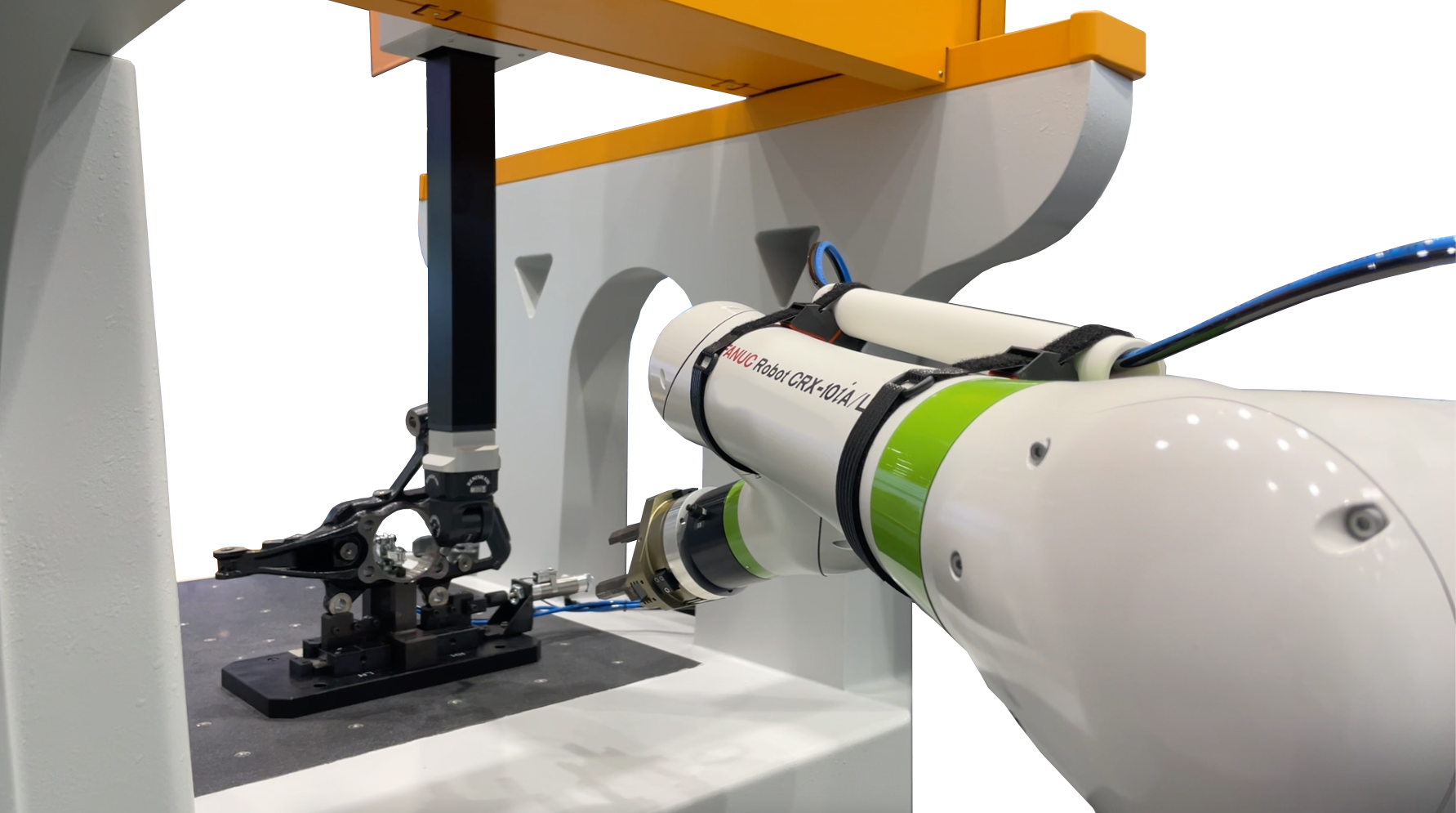

Automation, AI and 5-axis CMMs team up to create versatile manufacturing cells. AIMS understands manufacturing needs. We are continuing to evolve with the ever changing needs of the manufacturing sector. In this article we discuss the needs for flexible inspection cells to adapt to the product mix that is in demand.AIMS Metrology (Advanced Industrial Measurement Systems) announced it has partnered with Optical Gaging Products (OGP). The affiliation with OGP will enable AIMS to provide multisensor measurement with optical gaging products including Smartscope E-Series.

Songwriter Bob Dylan penned the words to his hit song “The Times They Are a-Changin” in 1964. Its’ message — that change is a constant…and anything that appears one way now may appear differently in the future — is especially relevant today for job shops, fabricators and manufacturers.

DAYTON, Ohio—(October 17, 2022) AIMS Metrology, a 5-axis coordinate measuring machine OEM, appointed Thomas Ayers sales and business development director for the Southeast region. With more than 30 years of experience in the metrology industry, Ayers has served the automotive, aerospace, medical, plastic and metal cutting markets in the areas of training, fixture development, turnkey programming and automated systems.

Klaus Schwab, founder and executive chairman of the World Economic Forum, coined the phrase the Fourth Industrial Revolution in 2015. That same year North American metalworkers and fabricators were introduced to Industry 4.0. Schwab said, “we are at the beginning of a revolution that is fundamentally changing the way we live, work and relate to one another.” He believed this fusion of physical, digital and biological spaces would impact all disciplines, economies and industries. And in many ways it has, from the rise of artificial intelligence, robotics and 3D printing to quantum computing.

We’ve all heard it—that persuasive argument that attempts to coax us into replacing our cell phone because the newest model has a better camera, longer battery life, or faster chip. Consumer products typically are phased out on a regular basis to make room for their new and improved counterparts. Job shops and manufacturers also struggle to balance legacy machines with new capital equipment purchases including coordinate measuring machines (CMM).

.png)