CMMs and Their Future in Manufacturing

We all know that Coordinate Measuring Machines (CMMs) measure the geometry of physical objects by...

AIMS Metrology Blog

We all know that Coordinate Measuring Machines (CMMs) measure the geometry of physical objects by...

Whether used in a lab environment or on a shop floor, coordinate measurement machines (CMMs) can...

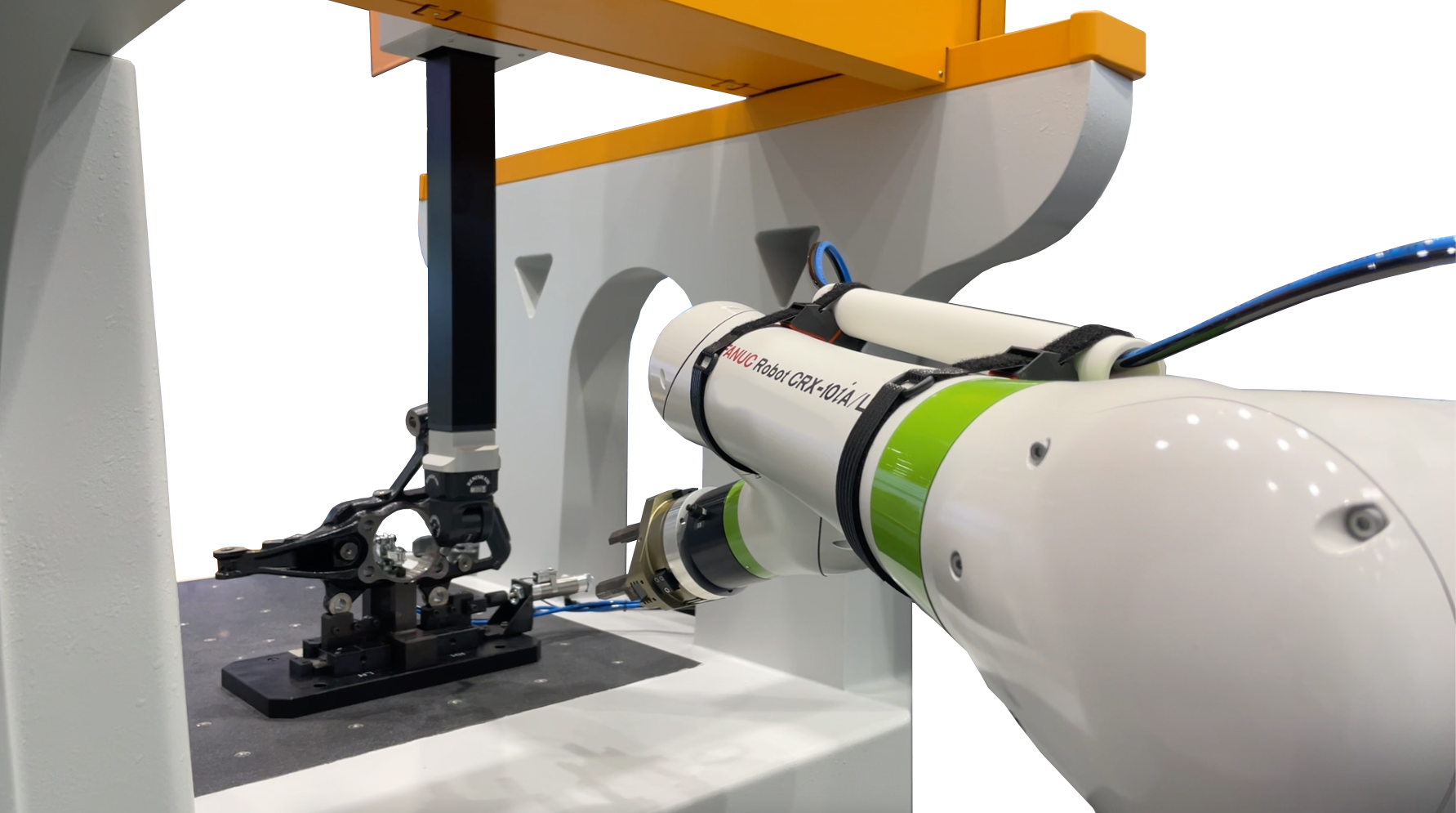

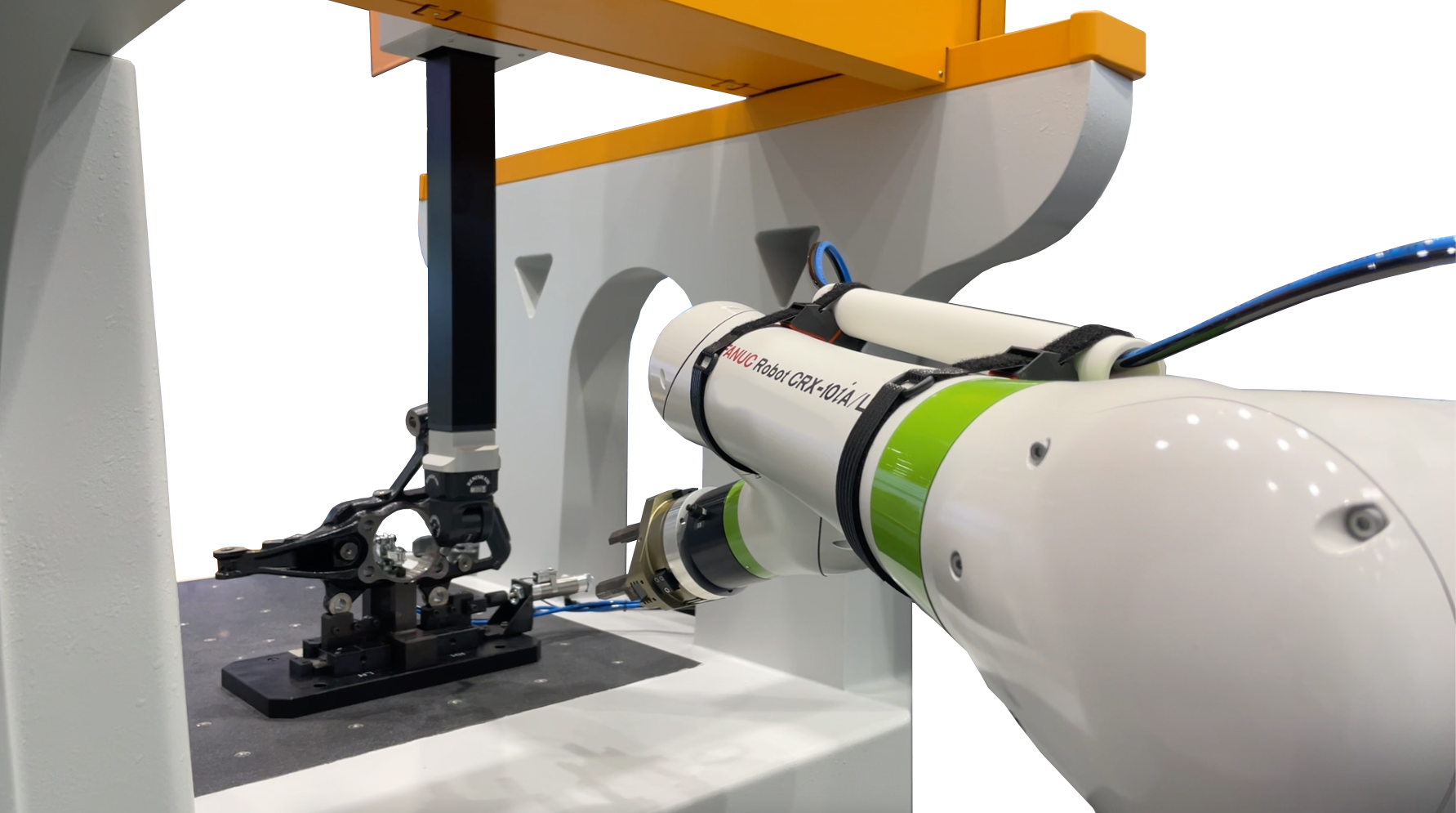

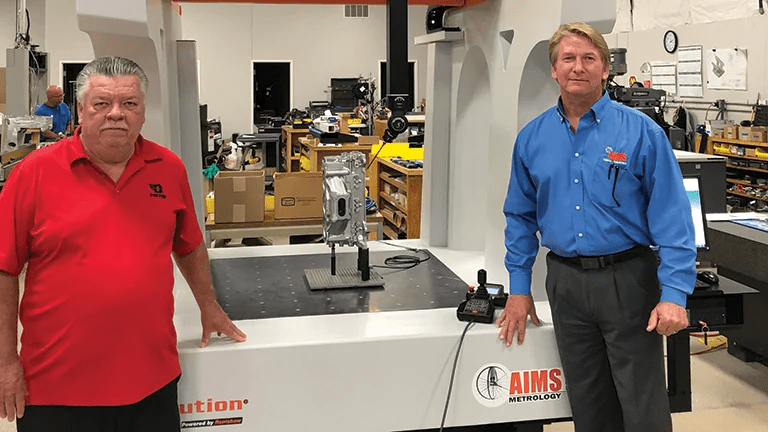

AIMS recently provided another 5-axis solution in the southeast to a global leader in power system...

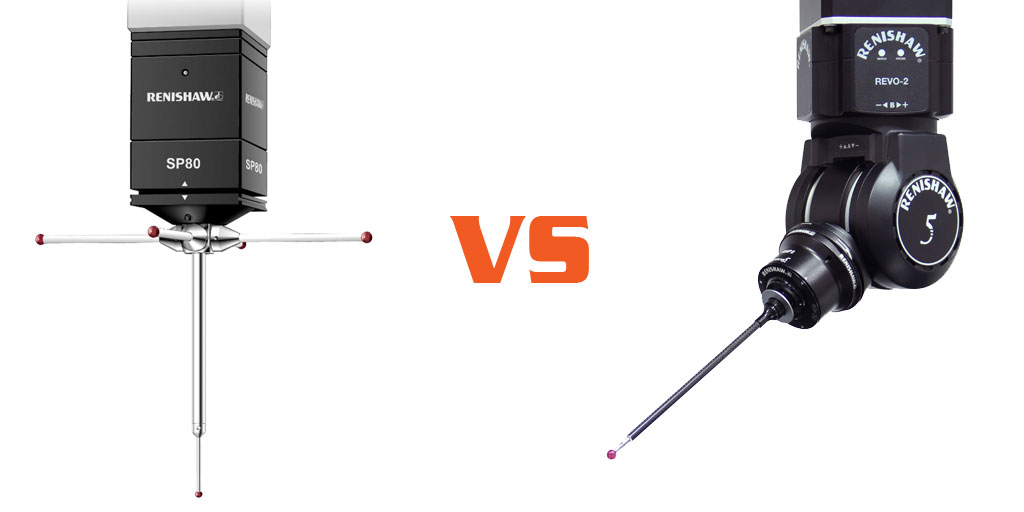

A 5-axis Coordinate Measuring Machine (CMM) is a powerful tool for measuring complex shapes and...

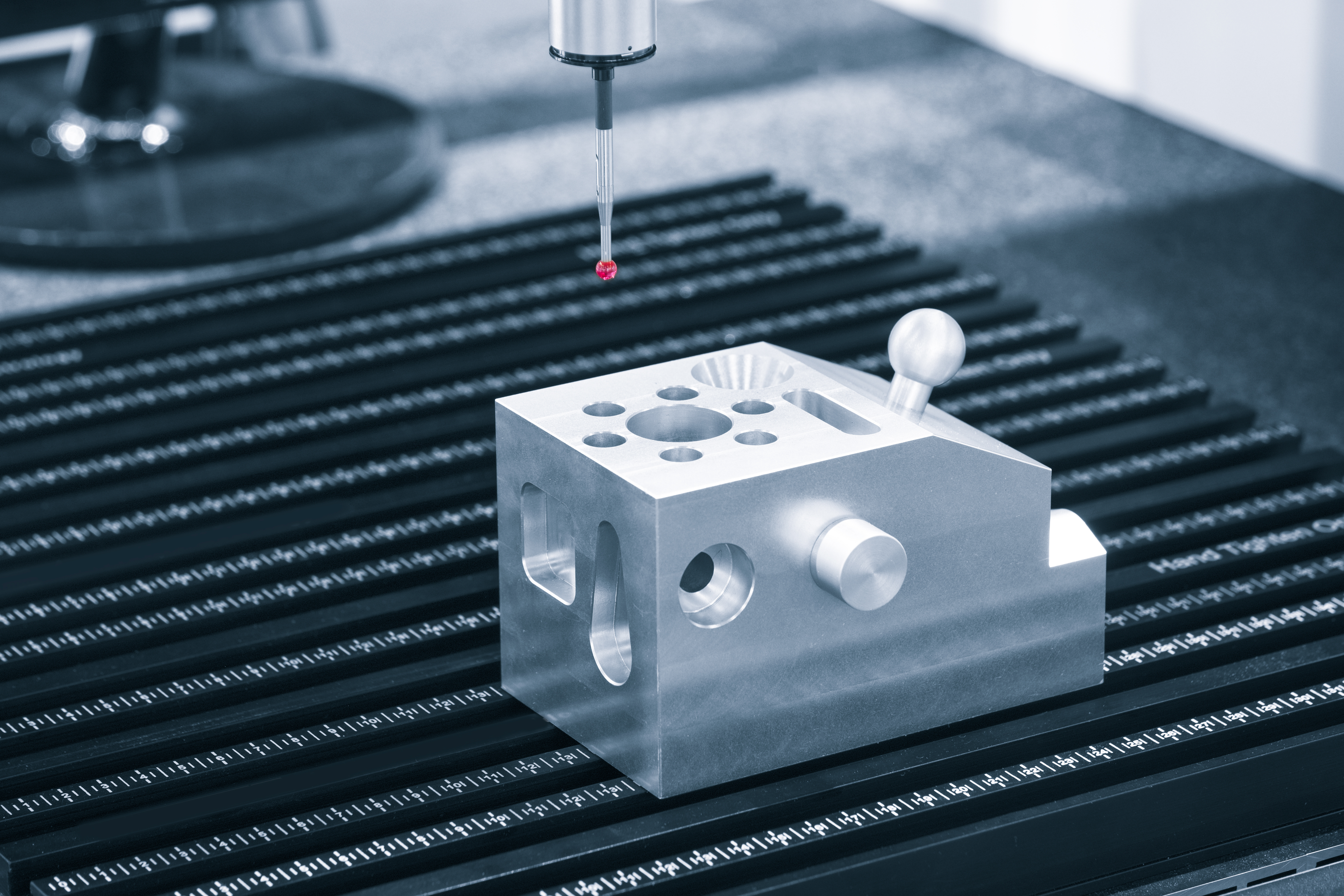

Coordinate measuring machines, commonly referred to as CMM machines, measure the geometry of...

A coordinate measuring machine (CMM) measures the geometry of certain physical objects along their...

As Christmas Day approaches, another year comes to a close. According to Forbes, it has become a...

If you talk to a service center or manufacturer these days, they’ll tell you the supply chain...

Supply chain blockages have prompted major U.S. ports like Los Angeles, and companies like UPS and...

Don't have time to read this article? Watch it instead!

Global accounting network, BDO, recently...

Don't have time to read the article? Watch it instead!

For more than two decades, Capital One...

Do you have a favorite Marvel superhero? Maybe it’s Thor, the god of thunder, the Avengers, Captain...

Don't have time to read this article? Watch it instead!

Linearity is a term used to describe...

Although our clients recognize the need for precise metrology solutions, buyers are not always...

Don't have time to read the article? Watch it instead!

A retrofit will extend the service life and...

Electric cars with their “green” electric motors continue to grab the spotlight, having unseated...

You'll start to see a surge in consumers purchasing electric vehicles (EVs) and hybrids in the near...

Don't have time to read this article? Watch it instead!

In the early 1950s, George C. Devol...

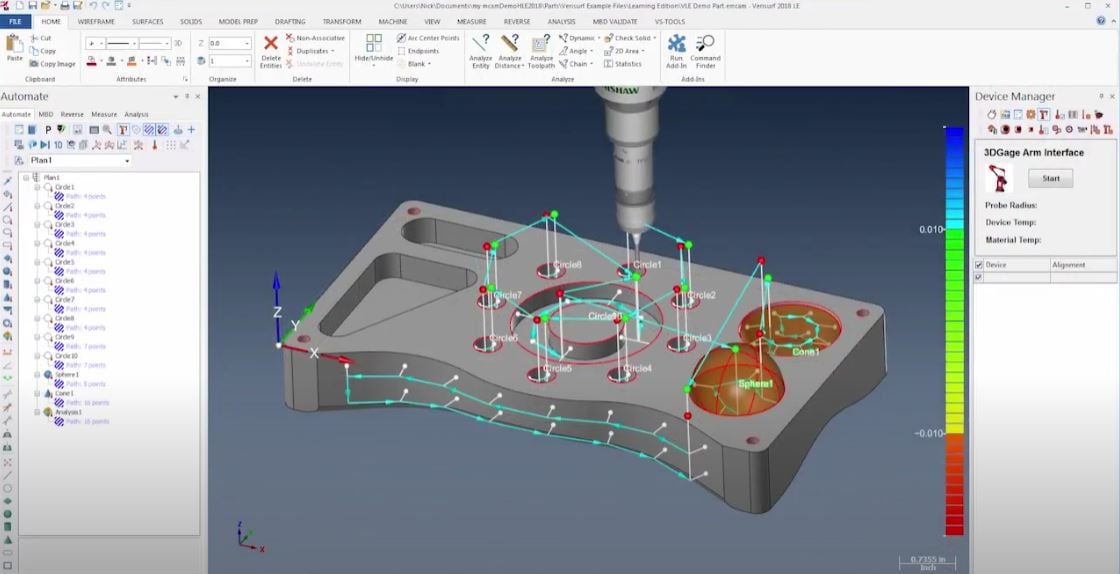

A Brief Guide to CMM Software

Commercial air travel is expected to make a slow recovery according to a recent Deloitte Aerospace...