Originally published in CMM Quarterly Magazine at http://cmmquarterly.mbccmm.com/index.php/current-issue/93-past-articles/232-the-revolution-is-on-the-move-the-only-mobile-5-axis-shop-floor-cmm.

Isn’t convenience nice? I know I enjoy it, and I think it’s safe to say that everyone does. You have to admit, when you see that batteries are in fact included with your purchase, you feel just a little relieved and happy. Or, when you want to buy chips and chip dip, and lo and behold, the grocery store added a stand-alone rack full of dip right next to your favorite flavor, you think that it’s, well, nice and convenient.

At work, we all set up our own little conveniences too, whether we know it or not. We place our pens and pencils together in holders. We place our hammers, screwdrivers, nuts and bolts together and in the same spot.

So, how did we make CMMs convenient for ourselves? We created change racks to hold our probes together, created stylus kits to keep all styli together and in the same spot…

All these are helpful, but I think in the process of trying to make all the components convenient, the machine – the CMM itself – got overlooked. Nothing about having to buy three CMMs – one for mobility, one for life on a shop floor, and another for 5-axis capabilities – is convenient.

So, a solution was made, and its name is the Revolution®.

True to its title, the Revolution® HB 5.9.4 and 8.10.6 revolutionize the way we think of and operate CMMs. If you’re looking for versatility, you won’t find one any better than this – the Revolution® HB is the only CMM on the market that offers this 3-in-one deal.

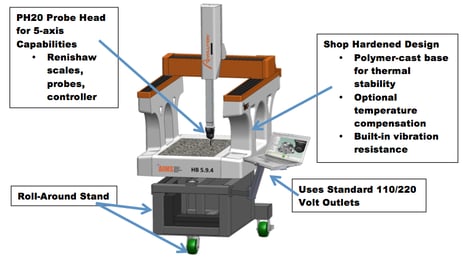

First off, supporting the weight of the machine, a roll around stand enables the CMM to be moved to wherever it is needed. If you’re putting together a machine line, and need it over near you for a while, you can roll it right on over. If your coworker needs to inspect a part, the CMM can be moved again. What’s unique about this set-up is that once you have it where you need it, the casters can be tightly locked. Once they are, the Revolution® essentially gets locked in place and couldn’t budge if you tried.

The other added feature to the Revolution® HB’s mobility are its utilization of 110 and 220 volt outlets. Because there’s no need for shop air, all you have to do is unplug when you want to move the CMM, then plug it back in in the new spot.

Firmly attached to the stand, the Revolution’s® polymer-cast base includes built-in vibration resistance and thermal stability. The mechanical bearings on this machine also further help to dampen the vibration abuse a CMM would normally receive in shop floor environments. The Revolution® HB can stand in the midst of the shop floor and can completely provide the best repeatability and precise accuracy than other CMM’s on the market. This was intended with the thought of a fully shop hardened design – to maximize everything to the highest degree while in harsh conditions.

The last component to this trifecta: 5-axis performance. Renishaw had a nice idea when they created a probe head with 5-axis capabilities. Called the PH20, it is now the centerpiece of the Revolution® HB models. PH20 uses an innovative process called “head touches”, where measurement points are taken by moving only the head, rather than the whole CMM structure. Only by using the rapid rotary motion of its head, which moves in two rotary axes, it can dish out drastically improved accuracy and repeatability because it doesn’t rely on the machine itself to aid it, doing a job it wasn’t meant to do.

We had a recent customer who couldn’t get over how incredibly fast and efficient the Revolution® and PH20 together were for the jobs he was doing. Before he bought it, he would have to make some very complicated parts for a client in the defense industry – for which he used a sine bar and an optical comparator for surface profiling, which took him 2 to 3 days to inspect. With his new machine and the added effects of the PH20, he “…literally cut that time to 9 to 12 minutes!”

Needless to say, Renishaw technology is what the Revolution® is equipped for. Renishaw’s incremental encoder system, probes, and controller also come with this CMM.

The Revolution® HB was an idea conceived with all of the above in mind – and that now, there is an option out there. To give CMM operators the ability to be as versatile as they want to be with the dynamic capabilities of an all-in-one CMM is what the Revolution® HB is all about. CMM’s don’t have to be built by the book – one for this capability, one for that. Operators need something that will revolve around what they need to do, not the other way around. So, with that in mind, do some research to see what I’m talking about. You might like the idea of a dynamic CMM.