Need Help? AIMS Has Your Back

Supply chain blockages have prompted major U.S. ports like Los Angeles, and companies like UPS and...

Supply chain blockages have prompted major U.S. ports like Los Angeles, and companies like UPS and...

Don't have time to read the article? Watch it instead!

For more than two decades, Capital One...

Baby boomers are retiring at the rate of approximately 10,000 a day. In their wake, Millennials are...

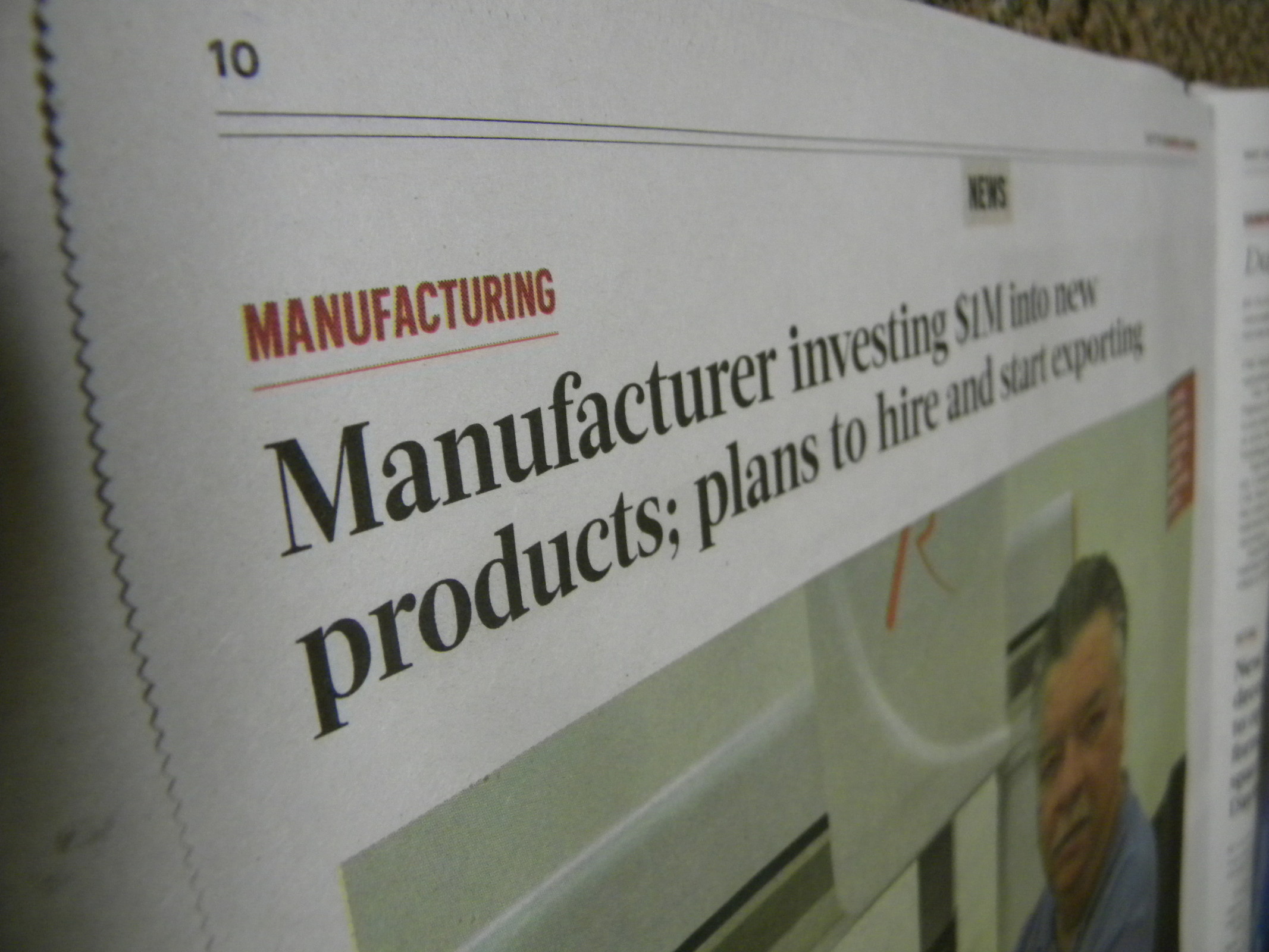

In the metal fabrication business, most companies are small to...

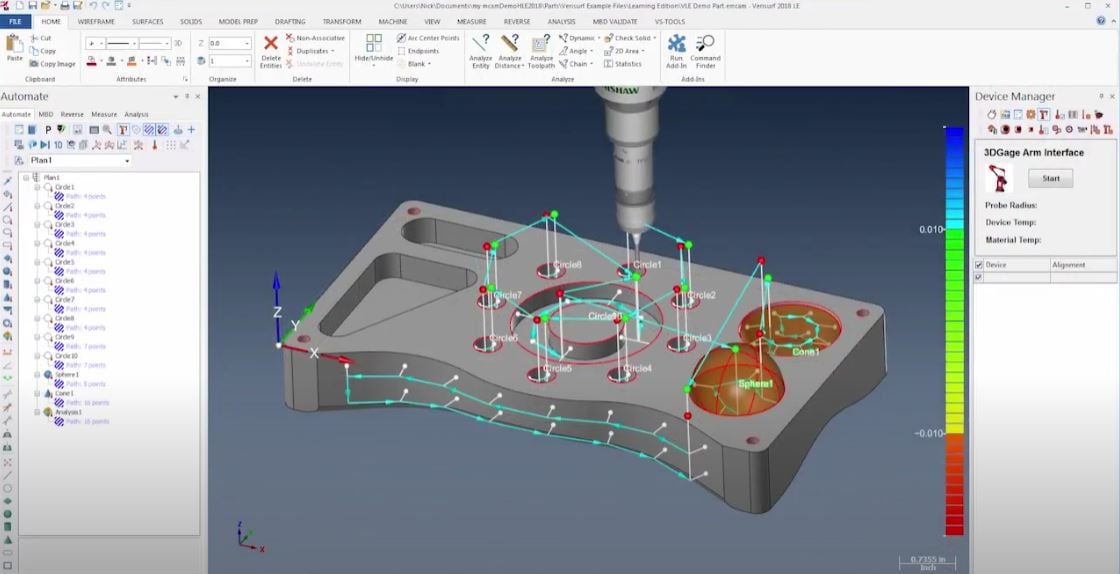

When it comes to coordinate measuring machines (CMMs) most of us focus on what’s right in front of...

If you look at customer service trends for 2018 you are likely to read about things like chat...

Global Industry Analysts reports that by 2020, an increasing focus on quality is expected to push...

Philippe Cochet, GE’s chief productivity officer, wrote in a recent GE Report that “advanced...

Benjamin Franklin said, “The doors of wisdom are never closed.” Depending on your perspective, his...

"It's a jungle out there." The idiom was coined to describe situations considered dangerous or...

"Count the cost" is a phrase that's hung over most of us at one time or another like an ominous...

Remember the Maytag Repairman? He emerged in television commercials during the 1960s as the...

When it comes to OEM service and support for coordinate measuring machines, it should be a no...

“It's always best to start at the beginning--and all you do is follow the Yellow Brick Road.”

This...