Over the years I’ve often heard it said that it is the little things that make the big things happen. In recent years, digitization has put the spotlight on software tools as a means to improve CMM performance. But software can only take one so far. Getting back to basics—good designs and sound engineering—are the keys to high-performing CMM technology.

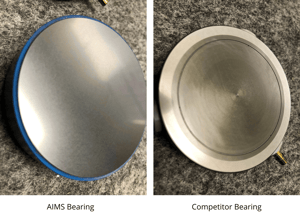

Take bearings for example. The tiny part supports a CMM’s moving components but not all bearings are created equal. Conventional aluminum air bearings typically are produced with several orifices designed in a pattern across the smooth face of the bearing pad. These openings distribute pressurized air which gives the machine lift to move without dragging. The downside to this design becomes apparent if the guideway sustains a nick— a common occurrence in a job shop environment—or has a minute imperfection. When the bearing passes over the nick, the interruption in air flow causes the machine to lose lift and dip before it recovers. That small dip can make a big impact on accuracy.

AIMS engineers chose to equip the Revolution Series LM with a bearing design that uses a graphite porous surface. Because air travels through the pores, if the bearing travels over a nick or imperfection, it only loses air at that specific point. It doesn’t bleed or lose air like an aluminum bearing.

On the LM, the air pressure of each axis is controlled independently providing improved lift. The Y axis has two air bearing regulators, one for the drive side which contains four bearings and one for the outboard leg. This allows the machine to manage lift of the two sides independently. Machines with just one regulator have a tendency to experience yaw [twist or oscillate about a vertical axis] when there is a lift differential from side to side.

In addition to improved control of machine lift, the LM’s linear motors don’t having any moving parts to bind, generate noise or slip, which makes the machine ideal for scanning applications where precision movement is required. Other CMMs on the market use friction drives, belt drives, and rack and pinion drives which are poor candidates for scanning probes due to loose machine positioning. Part scanning typically requires extremely slow velocities and accelerations to maintain the scanning probe within allowable deflection ranges.

In addition to the LM’s superior bearing design and linear motors, AIMS determines the right balance of air pressure for the CMM before it leaves the shop floor. Once the CMM is installed, technicians adjust air pressure balance again.

We believe the smallest details are important when it comes to providing accurate measurements and high throughput. As lead times continue to shrink, the ability to achieve accurate measurements quickly can mean the difference between falling behind or staying ahead of the competition.