FABTECH is North America's largest metalforming, fabricating, welding and finishing event, held every November at one of three rotating venues. This year, FABTECH opened to vendors, exhibitors and visitors in Chicago at McCormick Place. With more than 750,000 sq. ft. of floor space dedicated to approximately 1,700 world-class suppliers and the latest in industry products and developments, you're bound to see some interesting things.

For example, OMAX, a waterjet OEM with a long pedigree, introduced the first high-performance abrasive personal waterjet. The company is targeting the makerspaces to attract passionate hobbyists. OMAX is also courting academia in the hopes of getting young people excited about making stuff. Advanced software algorithms and 30 ksi pump pressure drives the machine which can cut pretty much anything up to 1 in. thick.

Smart software was a huge topic among equipment manufacturers. We’re talking about products that can give you a bird’s eye view of your entire processing line or zero in on a single machine for all kinds of intel. Things like, "My machine is on but it’s idling. Why? Is it waiting for material? Is my operator at optimum performance or are they getting fatigued? Maybe they simply can’t keep up. Is it time to automate?" It’s all about being transparent so you can identify a problem before it becomes a problem and still meet your deliverables.

But it’s not just about the hardware and the software - you also meet some interesting people. Take for example the Knapp family. Kent and Shannon, their daughter Zoey Rae and their sons Oscar, Birdie and Miles all work the family business and were first time FABTECHers. In fact you may have their TV show on the History Channel, Milwaukee Blacksmith. They stopped by the PFERD booth to chat with folks like John Thompson who spent time training the family on using its finishing products to introduce new capabilities that compliment Kent’s old-school forging skills.

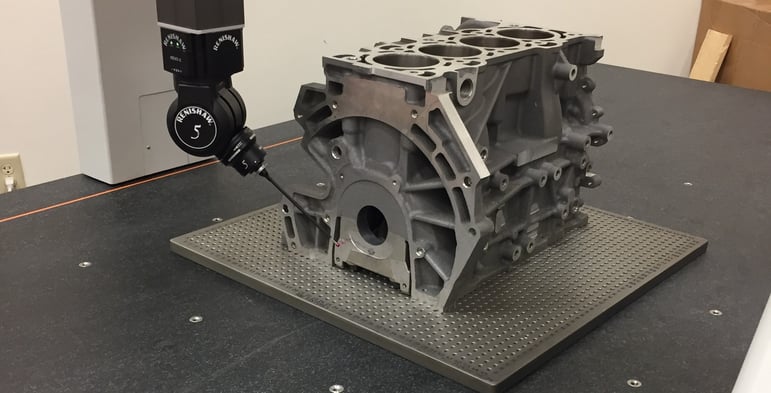

I also spoke with Jeffrey Seliga, marketing manager for Renishaw Inc, in the company's booth. In addition to its 5-axis CMM probes, the company is a leader in metal 3D printing. Over the last five years, additive manufacturing has gained ground in industries such as aerospace, automotive and medical.

Renishaw offers a total additive manufacturing solution from systems, metal powders, ancillaries and software to support after-the-sale service. Designed and built by Renishaw, its systems meet the needs of a variety of industries including dental, medical, mould tooling, industrial tooling and aerospace. 3D printing is just one of the advances that's making its way into mainstream manufacturing and in many cases ending up on the floor of a job shop or contract manufacturer. It’s part of new Industrial Internet of Things landscape.

It also means coordinate measuring machines are going to play a bigger role than ever with requirements for part validation and verification ramping up as components become more intricate with closer tolerances. CMMs with 5-axis measurement capability and the capacity to deliver touch probe or noncontact scanning offer a key component to an advancing supply chain that likely will leave traditional measurement systems behind. One example of this is the AIMS Revolution HB Shop Floor CMM. It's built to fully optimize the Renishaw PH20 probe head, allowing the operator to perform 5-axis measurement right on the shop floor.

Questions on 5-axis, Renishaw probes or anything else? Contact us anytime.