Linear Motor CMM

While most electric motors have round stators and rotors to produce rotational force known as torque, linear motors are longer and have straight stators and rotors to create linear force. Low- and high-acceleration models operate slowly over long distances or quickly over short distances, respectively.

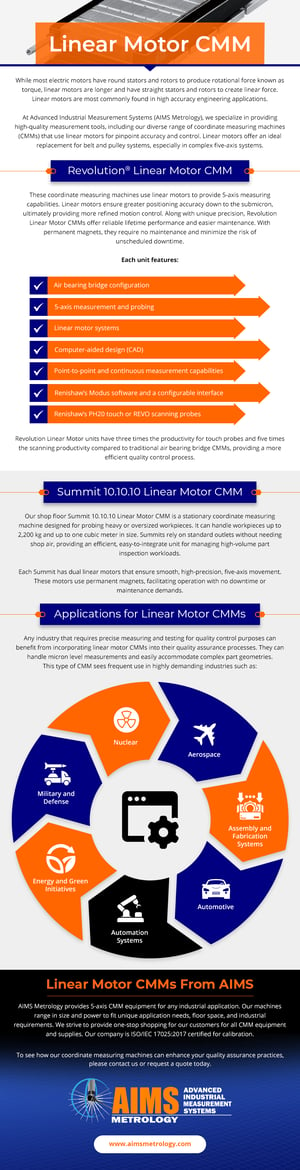

At Advanced Industrial Measurement Systems (AIMS Metrology), we specialize in providing high-quality measurement tools, including our diverse range of coordinate measuring machines (CMMs) that use linear motors for pinpoint accuracy and control. Linear motors offer an ideal replacement for belt and pulley systems, especially in complex five-axis systems.

Revolution® Linear Motor CMM

These coordinate measuring machines use linear motors to provide 5-axis measuring capabilities. Linear motors ensure greater positioning accuracy down to the submicron, ultimately providing more refined motion control. Along with unique precision, Revolution Linear Motor CMMs offer reliable lifetime performance and easier maintenance. With permanent magnets, they require no maintenance and minimize the risk of unscheduled downtime.

Each unit features:

- Air bearing bridge configuration

- 5-axis measurement and probing

- Linear motor systems

- Computer-aided design (CAD)

- Point-to-point and continuous measurement capabilities

- Renishaw’s Modus software and a configurable interface

- Renishaw’s PH20 or REVO touch or scanning probes

Revolution Linear Motor units have three times the productivity and five times the scanning productivity compared to traditional air bearing bridge CMMs, featuring more efficient quality control and compliance.

Summit 10.10.10 Linear Motor CMM

Our shop floor Summit 10.10.10 Linear Motor CMM is a stationary coordinate measuring machine designed for probing heavy or oversized workpieces. It can handle workpieces up to 2,200 kg and up to one cubic meter in size. Summits rely on standard outlets without needing shop air, providing an efficient, easy-to-integrate unit for managing high-volume part inspection workloads.

Each Summit has dual linear motors that ensure smooth, high-precision, five-axis movement. These motors use permanent magnets, facilitating operation with no downtime or maintenance demands.

Applications for Linear Motor CMMs

Any industry that requires precise measuring and testing for quality control purposes can benefit from incorporating linear motor CMMs into their quality assurance processes. They can handle measurements down to the submicron and easily accommodate oversized products. This type of CMM sees frequent use in highly demanding industries such as:

- Aerospace

- Assembly and fabrication systems

- Automotive

- Automation systems

- Energy and green initiatives

- Military and defense

- Nuclear

Linear Motor CMMs From AIMS

AIMS Metrology provides 5-axis CMM equipment for any industrial application. Our machines range in size and power to fit unique application needs, floor space, and industrial requirements. We strive to provide one-stop shopping for our customers for all CMM equipment and supplies. Our company is ISO/IEC 17025:2005 certified for calibration.

To see how our coordinate measuring machines can enhance your quality assurance practices, please contact us or request a quote today.