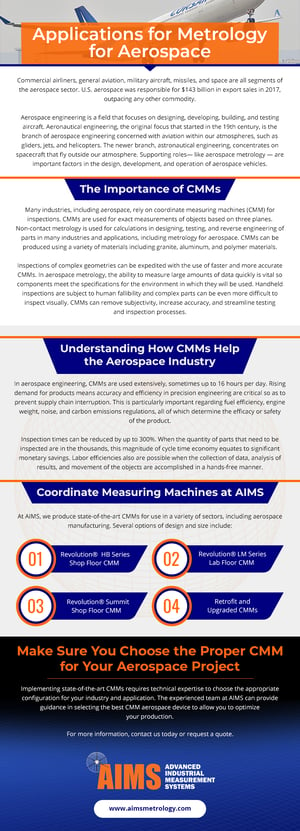

Applications for Metrology for Aerospace

Commercial airliners, general aviation, military aircraft, missiles, and space are all segments of the aerospace sector. U.S. aerospace was responsible for $143 billion in export sales in 2017, outpacing any other commodity.

Aerospace engineering is a field that focuses on designing, developing, building, and testing aircraft. Aeronautical engineering, the original focus that started in the 19th century, is the branch of aerospace engineering concerned with aviation within our atmospheres, such as gliders, jets, and helicopters. The newer branch, astronautical engineering, concentrates on spacecraft that fly outside our atmosphere. Supporting roles— like aerospace metrology — are important factors in the design, development, and operation of aerospace vehicles.

The Importance of CMMs

Many industries, including aerospace, rely on coordinate measuring machines (CMM) for inspections. CMMs are used for exact measurements of objects based on three planes. Non-contact metrology is used for calculations in designing, testing, and reverse engineering of parts in many industries and applications, including metrology for aerospace. While they can be made from a variety of materials, granite and aluminum are the most widely adopted.

Inspections of complex geometries can be expedited with the use of faster and more accurate CMMs. In aerospace metrology, the ability to measure large amounts of data quickly is vital so components meet the specifications for the environment in which they will be used. Handheld inspections are subject to human fallibility and complex parts can be even more difficult to inspect visually. CMMs can remove subjectivity, increase accuracy, and streamline testing and inspection processes.

Understanding How CMMs Help the Aerospace Industry

In aerospace engineering, CMMs are used extensively, sometimes up to 16 hours per day. Rising demand for products means accuracy and efficiency in precision engineering are critical so as to prevent supply chain interruption. This is particularly important regarding fuel efficiency, engine weight, noise, and carbon emissions regulations, all of which determine the efficacy or safety of the product.

Inspection time, in some cases, reduced cycle time by up to 40%. When the parts need to be inspected number in the thousands, this magnitude of cycle time economy equates to significant monetary savings. Labor efficiencies also are possible when the collection of data, analysis of results, and movement of the objects are accomplished in a hands-free manner.

Coordinate Measuring Machines at AIMS

At AIMS, we produce state-of-the-art CMMs for use in a variety of sectors, including aerospace manufacturing. Several options of design and size include:

- Revolution® HB Shop Floor CMM. The market's only mobile 5-axis shop floor CMM.

- Revolution® Air Bearing Small Bridge CMM. The solution where speed and ease of use are critical, this machine is ideal for everything from incoming inspection to process control and final inspection.

- Revolution® Air Bearing Large Bridge CMM. Available in a variety of sizes, this heavy-duty machine is designed for precision inspection of larger components.

- Revolution® Linear Motor CMM. The air bearing bridge configuration of this CMM, features measuring platforms utilizing the next generation 5-axis probing technology.

Make Sure You Choose the Proper CMM for Your Aerospace Project

Precision engineering and inspection of aerospace components are critical. The ability to increase production in response to higher demand depends on the ability to conduct efficient and accurate inspections. Accurate measurements can detect variances to specifications and ensure compliance with environmental protection standards.

Implementing state-of-the-art CMMs requires technical expertise to choose the appropriate configuration for your industry and application. The experienced team at AIMS can provide guidance in selecting the best CMM aerospace device to allow you to optimize your production. For more information, contact us today or request a quote.